|

| 品牌 | 沙伯基础 |

| 货号 | V0150B |

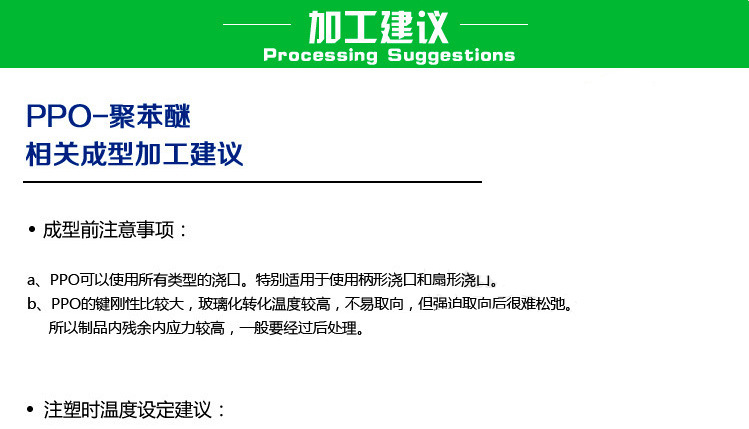

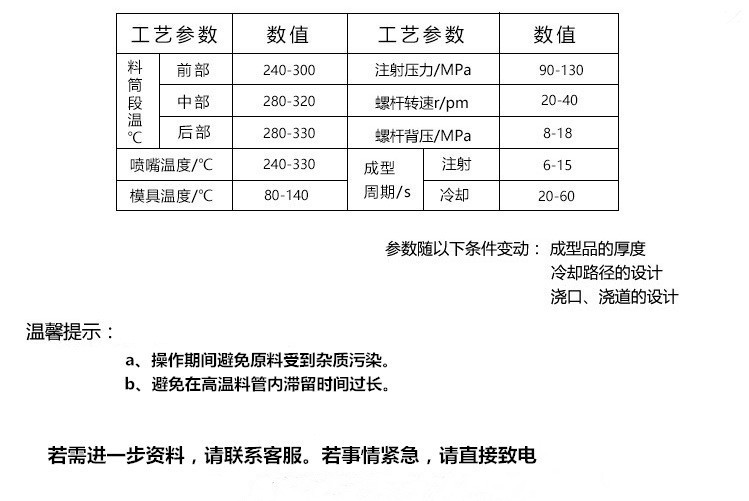

| 用途 | 注塑 |

| 牌号 | V0150B |

| 型号 | V0150B |

| 品名 | PPO |

| 外形尺寸 | 颗粒 |

| 厂家 | 沙伯基础 |

| 是否进口 | 是 |

规格用途

| 规格级别 | 外观颜色 | ||

| 该料用途 | |||

| 备注说明 | |||

技术参数

| 性能项目 | 试验条件[状态] | 测试方法 | 测试数据 | 数据单位 | |

| 物理性能 | 比重 | ASTMD792 | 1.11 | g/cm3 | |

| 密度 | ISO1183 | 1.11 | g/cm3 | ||

| 熔流率(熔体流动速率)(280°C/5.0kg) | ASTMD1238 | 3.5 | g/10min | ||

| 溶化体积流率(MVR)(300°C/5.0kg) | ISO1133 | 10.0 | cm3/10min | ||

| 收缩率-流动 | --2 | InternalMethod | 0.50to0.70 | % | |

| 3.20mm | InternalMethod | 0.50to0.70 | % | ||

| 吸水率(饱和,23°C) | ISO62 | 0.18 | % | ||

| 吸水率(平衡,23°C,50%RH) | ISO62 | 0.060 | % | ||

| 机械性能 | 拉伸模量3 | ASTMD638 | 2500 | MPa | |

| 拉伸模量 | ISO527-2/1 | 2500 | MPa | ||

| 抗张强度4(屈服) | ASTMD638 | 70.0 | MPa | ||

| 拉伸应力(屈服) | ISO527-2/50 | 70.0 | MPa | ||

| TensileStrength4(Break) | ASTMD638 | 60.0 | MPa | ||

| 拉伸应力(断裂) | ISO527-2/50 | 55.0 | MPa | ||

| 伸长率4(屈服) | ASTMD638 | 5.0 | % | ||

| 拉伸应变(屈服) | ISO527-2/50 | 4.0 | % | ||

| 伸长率4(断裂) | ASTMD638 | 7.0 | % | ||

| 拉伸应变(断裂) | ISO527-2/50 | 10 | % | ||

| FlexuralModulus5(50.0mmSpan) | ASTMD790 | 2550 | MPa | ||

| 弯曲模量6 | ISO178 | 2400 | MPa | ||

| FlexuralStress6,7 | ISO178 | 110 | MPa | ||

| FlexuralStrength5(Yield,50.0mmSpan) | ASTMD790 | 105 | MPa | ||

| 泰伯耐磨性(1000Cycles,1000g,CS-17转轮) | InternalMethod | 35.0 | mg | ||

| 冲击性能 | 简支梁缺口冲击强度8 | -30°C | ISO179/1eA | 5.0 | kJ/m2 |

| 23°C | ISO179/1eA | 14 | kJ/m2 | ||

| 悬壁梁缺口冲击强度 | -30°C | ASTMD256 | 180 | J/m | |

| 23°C | ASTMD256 | 330 | J/m | ||

| 悬壁梁缺口冲击强度9 | -30°C | ISO180/1A | 5.0 | kJ/m2 | |

| 23°C | ISO180/1A | 13 | kJ/m2 | ||

| 装有测量仪表的落镖冲击(23°C,TotalEnergy) | ASTMD3763 | 50.0 | J | ||

| 硬度 | 球压硬度(H358/30) | ISO2039-1 | 113 | MPa | |

| 热性能 | HeatDeflectionTemperature10(0.45MPa,Unannealed,100mmSpan) | ISO75-2/Be | 140 | °C | |

| 载荷下热变形温度(1.8MPa,未退火,3.20mm) | ASTMD648 | 135 | °C | ||

| HeatDeflectionTemperature10(1.8MPa,Unannealed,100mmSpan) | ISO75-2/Ae | 130 | °C | ||

| 维卡软化温度 | ASTMD152511 | 155 | °C | ||

| -- | ISO306/A50 | 160 | °C | ||

| -- | ISO306/B50 | 145 | °C | ||

| -- | ISO306/B120 | 155 | °C | ||

| BallPressureTest | 125°C | IEC60695-10-2 | Pass | ||

| 140°C12 | IEC60695-10-2 | Pass | |||

| 线形热膨胀系数-流动(-40到40°C) | ASTME831 | 7.5E-5 | cm/cm/°C | ||

| 线形热膨胀系数-流动(23到80°C) | ISO11359-2 | 7.0E-5 | cm/cm/°C | ||

| 线形热膨胀系数-横向(-40到40°C) | ASTME831 | 7.5E-5 | cm/cm/°C | ||

| CLTE-Transverse(23to80°C) | ISO11359-2 | 9.0E-5 | cm/cm/°C | ||

| 导热系数 | ISO8302 | 0.27 | W/m/K | ||

| RTIElec | UL746 | 110 | °C | ||

| RTIImp | UL746 | 105 | °C | ||

| RTIStr | UL746 | 115 | °C | ||

| 电气性能 | 表面电阻率 | IEC60093 | >1.0E+15 | ohms | |

| 体积电阻率 | IEC60093 | 1.0E+15 | ohms·cm | ||

| 介电强度 | 0.800mm,在油中 | IEC60243-1 | 33 | kV/mm | |

| 1.60mm,在油中 | IEC60243-1 | 26 | kV/mm | ||

| 3.20mm,在油中 | IEC60243-1 | 16 | kV/mm | ||

| 相对电容率 | 50Hz | IEC60250 | 2.80 | ||

| 60Hz | IEC60250 | 2.80 | |||

| 1MHz | IEC60250 | 2.70 | |||

| 耗散因数 | 50Hz | IEC60250 | 9.0E-4 | ||

| 60Hz | IEC60250 | 9.0E-4 | |||

| 1MHz | IEC60250 | 3.0E-3 | |||

| 漏电起痕指数 | IEC60112 | 250 | V | ||

| 可燃性 | UL阻燃等级 | 1.5mm | UL94 | V-0 | |

| 2.0mm | UL94 | 5VA | |||

| 灼热丝易燃指数(1.0mm) | IEC60695-2-12 | 960 | °C | ||

| 热灯丝点火温度 | 1.0mm | IEC60695-2-13 | 775 | °C | |

| 2.0mm | IEC60695-2-13 | 775 | °C | ||

| 3.0mm | IEC60695-2-13 | 775 | °C | ||

| 极限氧指数 | ISO4589-2 | 32 | % | ||

返回

顶部